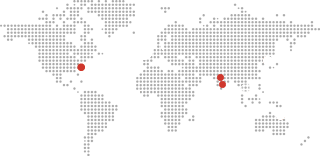

LocationINDIA & USACall Us: 855-208-2224

Mullite

Finest Mineral

MULLITE MINERAL

Malli Minerals International is a professionally managed enterprise actively engaged in the supplying of Mullite Minerals to global market.

Mullite is a naturally occurring mineral recognized for its exceptional heat resistance and high melting point. Formed during the firing of clay or alumina-rich materials, it is a critical component in ceramics and refractory products due to its ability to withstand extreme temperatures and provide structural stability.

Typical applications include

- Refractories : Mullite is a crucial component in refractory materials for lining high-temperature equipment like kilns and furnaces.

- Ceramic Production :It enhances ceramics’ heat resistance and mechanical strength, crucial for products like kiln furniture and crucibles.

- Aerospace : Mullite’s lightweight and high-temperature resistance make it valuable for aerospace components such as heat shields and rocket nozzles.

- Electronics: Used in electronic substrates and insulators due to its thermal stability and electrical insulating properties.

- Foundry Industry : Mullite serves as a refractory material for casting molds and cores in foundry applications.

- Metallurgy : It’s used to line furnaces in metallurgical processes for the production of metals and alloys.

- Glass Production : Mullite helps maintain high temperatures in glass manufacturing, preventing contamination of the glass melt.

- Solar Panels : It serves as a substrate material in solar panels, ensuring efficient energy conversion.

- Environmental Filters : Mullite is used in ceramic filters for pollution control due to its resistance to high temperatures and corrosive environments.

Product Typical

Characteristics

- Chemical Composition

- Crystal Structure

- Color and Appearance

- Density

- Thermal Stability

- Heat Resistance

- Mechanical Strength

- Electrical Properties

- Thermal Insulation

- Abrasion Resistance

- Chemical Inertness

- Applications and Uses

Malli Minerals International, Inc supplies mullite mineral to worldwide customers. Our in-house manufacturing facility processes of mullite in different mesh sizes as per our customer’s needs. We have access to abundant natural resources of mullite mineral to supply to our customers worldwide.

Enqire more

About the product please click here

Industrial

Headquarters

1451 E 8th Street, Jacksonville, FL 32206

locations

Offices located at

1451 E 8th Street, Jacksonville, FL 32206Chemiddi Village, Gudur Mandal, Nellor Dist., Andhra Pradesh, India

Warehouse

1451 E 8th Street, Jacksonville, FL 32206